There are two basic types of Reprocessing spent nuclear fuels

PUREX and Pyroprocessing

A couple simple definations from Wikipedia

PUREX is a chemical method used to purify fuel for nuclear reactors or nuclear weapons. It is an acronym standing for Plutonium Uranium Redox EXtraction. PUREX is the de facto standard aqueous nuclear reprocessing method for the recovery of uranium and plutonium from used ("spent", or "irradiated") nuclear fuel. It is based on liquid?liquid extraction ion-exchange.

Pyroprocessing is a process in which materials are subjected to high temperatures (typically over 800 ?C) in order to bring about a chemical or physical change. Pyroprocessing includes such terms as ore-roasting, calcination and sintering. Equipment for pyroprocessing includes kilns, electric arc furnaces and reverberatory furnaces.

Cement manufacturing is a very common example of pyroprocessing. The raw material mix is fed to a kiln where pyroprocessing takes place. As with most industries, pyroprocessing is the most energy-intensive part of the industrial process.

Argonne National Laboratory pioneered the development of pyrochemical processing, or pyroprocessing, a high-temperature method of recycling reactor waste into fuel. Today, Argonne National Laboratory researchers are developing and refining several pyroprocessing technologies for both light water and fast reactors, with most based on electrorefining rather than conventional wet-chemical/PUREX, to improve the technologies? commercial viability by increasing their process efficiency and scalability.

Before running off making highly exciting statements, we caution that the worlds largest and longest reprocessing company has been France's AREVA, now Framatome. They have processed steadfast for years on the original PUREX system.

Although the Pyroprocessing method is functioning, the research is STILL working to reach commercial viability. Only then will it be considered for corporate investment. These things STILL point profitable used nuclear fuels to the future.

Here is a link to a PDF article, 08-12-17: The Pyroprocessing Files

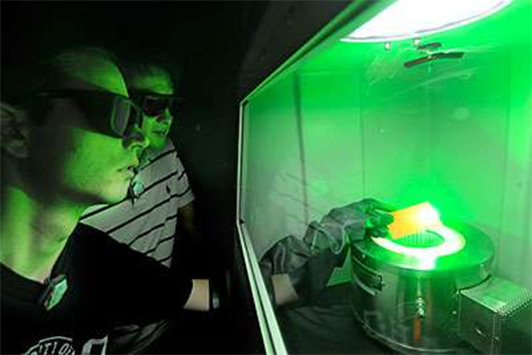

The human desire to forever continue to resolve obstacles which hinder the future continue to be in the cross-hairs of our RESEARCH! The future of nuclear fuels reprocessing is with, Laser-Induced Breakdown Spectroscopy.

Center for Advanced Energy Studies at Idaho National Laboratory

Another overview, laser research for Nuclear Recycling: Laser-Induced Breakdown Spectroscopy

A couple things to think about!